40 Years of Reform and Opening · Electronic Information Industry 丨 Integrated Circuits: Overall Enhancement of Industrial Strength

Date: 2019 / 11 / 30 Source: 网络整合 Browse: 780

Since the reform and opening up, China's electronic information industry has realized a major change from scratch to small and big, and its status and role in national economic and social development have significantly improved. Especially since the 18th National Congress of the Communist Party of China, China's electronic information industry has continuously made new progress, core technologies have gradually broken through, the market has continued to expand, and patents and standardization have achieved fruitful results. In order to reflect all aspects of the development of China's electronic information industry, China Electronics News specially planned to launch a special issue of "40 years of reform and opening up · Electronic Information Industry", inviting competent authorities, experts and scholars to write articles, from integrated circuits, electronic applications, electronic special equipment, Materials, ultra-high-definition video industry, color TV, electronic components, sensors, etc., talk about the main achievements of the electronic information industry in various fields since the reform and opening up, and propose ideas for the high-quality development of China's electronic information industry in the new era.

Integrated circuits are an important support for cultivating strategic emerging industries and developing the information economy, and have a prominent core position in the field of information technology. After the reform and opening up, China accelerated the construction of the integrated circuit industry, and started major projects such as the 908 project and the 909 project, and the integrated circuit industry achieved rapid development. Especially since the 18th National Congress of the CPC, the strength of China's integrated circuit industry has been rapidly improved. China's integrated circuit industry sales increased from 250.85 billion yuan in 2013 to 541.13 billion yuan in 2017, doubling in five years. From January to September 2018, China's integrated circuit industry sales were 446.15 billion yuan, a year-on-year increase of 22.4%.

IC design faucet with action increasingly obvious

IC design is the leader of the integrated circuit industry chain. The development of design companies directly affects many links in the upstream and downstream of the industrial chain such as manufacturing and packaging. In recent years, China's IC design industry has developed very rapidly. Data from the China Semiconductor Industry Association's Integrated Circuit Design Branch shows that by the end of 2018, there were 1,698 design companies across the country, an increase of 318 from 1380 last year, an increase of 23%. This is a significant increase in the number of design companies after the number of design companies increased by more than 600 in 2016. In terms of statistics, in addition to the traditional design enterprises in Beijing, Shanghai and Shenzhen, the number of design enterprises in Wuxi, Chengdu, Suzhou, Hefei and other cities is more than 100, and the number of design enterprises in cities such as Xi'an, Nanjing, and Xiamen is close. There were also 100 design enterprises in Tianjin, Hangzhou, Wuhan, Changsha and other places.

At the same time as the number of IC design companies has grown, companies above designated size have also increased. According to Wei Shaojun, chairman of the Integrated Circuit Design Branch of the China Semiconductor Industry Association, in 2018, 208 IC design companies are expected to have sales of more than 100 million yuan, an increase of 17 from 191 in 2017, an increase of 8.9%. At the same time, the total sales of these 208 companies with sales of over 100 million yuan reached 205.764 billion yuan, an increase of 28.615 billion yuan from the previous year's 177.149 billion yuan, accounting for 79.85% of the total sales of the industry.

Sales is an important indicator for measuring the development of an industry. The growth rate of China's IC design industry has maintained a double-digit level in recent years, and is much higher than the international average. , An increase of 32.42% over the 1945.098 billion yuan in 2017, an increase of 4.27 percentage points over the previous year's 28.15%. According to the exchange rate of 1: 6.8 USD and RMB, the annual sales reached USD 37.986 billion, and its proportion in the global integrated circuit design industry will increase again.

From the perspective of product types, the strength of Chinese companies in communication chips has gradually entered the international front-line camp. Ziguang Zhanrui has developed a 5G prototype pilot-v2 platform, and will launch 5G chips in 2019 to achieve commercialization of 5G chips. In 2018, the number of companies engaged in communication chip design increased from 266 in 2017 to 307, and the corresponding total sales increased by 16.34% to 104.675 billion yuan. In addition, computer chips and consumer chips also experienced strong growth. The number of companies engaged in computer chip design increased from 85 last year to 109, and sales increased by 180.18% to 35.941 billion yuan. The number of consumer electronics companies increased from 610 in the previous year to 783, and sales increased by 36.46% to 61.724 billion yuan, continuing the rapid growth momentum in 2017.

Established a relatively complete industrial chain

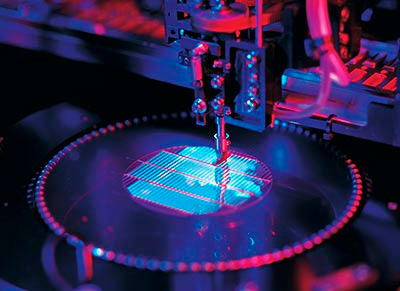

The development of design is inseparable from the support of industrial chains such as wafer manufacturing, packaging and testing, equipment, and materials. In the past, China's wafer manufacturing technology was about two generations away from the international advanced level. The gap in equipment and materials was even greater, but After years of catching up, it has been greatly improved.

At present, China's integrated circuits have formed a technology system suitable for them, and a relatively complete industrial chain has been established. The industrial ecology and competitiveness have been improved and enhanced, and multi-polar development in the Yangtze River Delta, the Pearl River Delta, Tianjin, Beijing, the Bohai Sea, and the central and western regions has been formed. Pattern. At present, 10 12-inch production lines have been completed, and many 12-inch production lines are under construction. These include companies such as SMIC, Huahong Group, Wuhan Xinxin and other local capital-led companies, as well as Intel, Samsung, and Georgia Silicon, TSMC foreign-invested or Taiwan-invested (single-owned or equity) enterprises. In terms of manufacturing technology, 65-nanometer, 40-nanometer, and 28-nanometer technologies have been mass-produced, breakthroughs have been made in the development of 14-nanometer technology, and the competitiveness of special technologies has improved. Memory is one of the general-purpose chips and is widely used. China has made significant progress and innovation in the research and development of 3D NAND technology, carried out research and development based on independent intellectual property rights, and proposed a new architecture Xtacking. This is also the first time that a Chinese company has proposed an important new architecture and technology path in the field of integrated circuits.

The packaging industry has always been a strong domestic sector. In recent years, it has actively promoted the development of advanced packaging and entered the high-end field from the low and mid-ends, greatly improving its competitiveness. According to the statistics of the China Semiconductor Industry Association Packaging Branch, the sales revenue of the domestic IC packaging and testing industry increased from 152.32 billion yuan in 2016 to 181.66 billion yuan in 2017, a year-on-year increase of 19.3%. The number of domestic IC packaging and testing industry enterprises was 96. The number of people reached 156,000. Changdian Technology has achieved mass production of highly integrated and high-precision SiP modules. Tongfu Microelectronics is the first to achieve mass production of 7nm FC products. Huatian Technology has developed a 0.25mm ultra-thin fingerprint packaging process to achieve 4G RF products. Mass production of PA.

The key equipment and materials have realized a change from scratch. The overall level has reached 28 nanometers, and some products have entered 14 nanometers to 7 nanometers, which are adopted by domestic and foreign production lines. Recently, the 5nm plasma etching machine independently developed by China Micro-Semiconductor has passed TSMC's verification and has excellent performance. It will be used in the world's first 5nm process production line. China Microelectronics entered TSMC's supply chain, proving that the strength of domestic semiconductor equipment is gradually growing.

Prior to this, TSMC's 7-nanometer chip production line also used micro-etchers. At present, the coverage rate of domestic key equipment varieties reaches 31.1%, and the coverage rate of advanced packaging equipment varieties is 80%.

In terms of materials, the quality of 200mm silicon wafer products has significantly improved, and high-quality polished wafers and epitaxial wafers have begun to enter the market. A breakthrough was made in the industrialization of 300mm silicon wafers. 90-65nm products passed user evaluation and began mass sales. The rake material and ultra-high-purity metal materials have achieved overall breakthroughs, forming a relatively complete rake material product system. Copper and barrier polishing fluids have a domestic market share of more than 50% and have entered the international market. NF3, WF6 and other gas industrialization technologies have reached the world's leading, with a domestic market share of more than 70%, and entered the international market. The independent supply capacity of phosphane, arsenic and safe ion source products.

Actively track the pace of new materials technology

The new material industry has become the precursor and cornerstone of the development of high-tech industries in the future. Among them, wide band gap semiconductor materials are one of the representatives of new materials. Since the 18th CPC National Congress, China has set off a wave of industrialization of wide-gap power semiconductor materials and devices. In December 2016, the State Council established the National Leading Group for the Development of New Materials Industry. In recent years, with the joint efforts of domestic enterprises, research institutes, universities, etc., more than ten 4-inch to 6-inch silicon carbide chip process lines and 6-inch to 8-inch silicon-based gallium nitride chip processes have been completed or are under construction It has formed a technology accumulation and narrowed the gap with foreign advanced levels.

The level of R & D and industrialization of silicon carbide epitaxial materials in China closely follows the international level, and products have entered the international market. In terms of industrialization, the level of silicon carbide epitaxial material products of 20 μm and below in China is close to the international advanced level; in terms of silicon carbide power devices, China has the capabilities of R & D of 1200V ~ 3300V SiC MOSFET, 1200V ~ 4500V SiC JFET, The chip current capacity is 25A. At present, many domestic enterprises have completed or are constructing multiple silicon carbide chip process lines. The commissioning of these process lines will greatly improve the industrialization level of domestic silicon carbide power devices.

Silicon-based gallium nitride material has significant cost advantages, easy to obtain large size, good thermal conductivity, and device preparation can be effectively compatible with traditional silicon integrated circuit CMOS process, which is a technical route generally used in the industry. China's development in the field of planar gallium nitride power devices follows the international pace. The wafer size is mainly 6 inches, and samples of silicon-based gallium nitride devices with voltage levels of 900V and below have been developed. In recent years, China has also begun the development of vertical gallium nitride power devices, and developed samples of gallium nitride diodes with a maximum blocking voltage of 1700V. China's gallium nitride radio frequency devices have achieved rapid development in recent years, and have formed industrialized companies, and their device performance has reached the international advanced level.